Blog

How to Choose the Best Geomembrane Welding Machine?

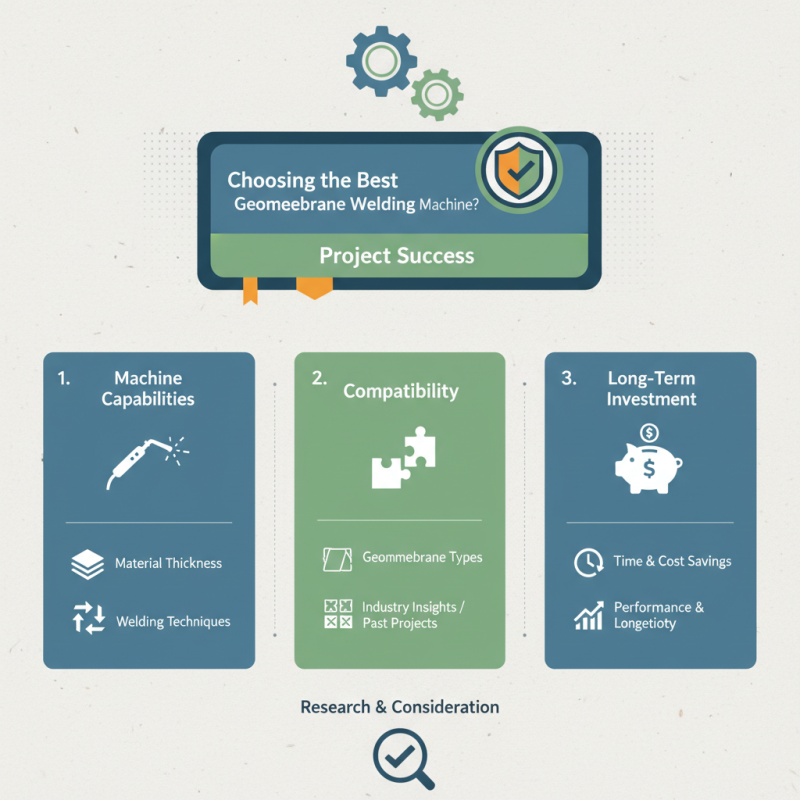

Choosing the right geomembrane welding machine is crucial for any project involving geomembrane installation. According to Dr. John Smith, a leading expert in geosynthetics, "Selecting the correct welding machine can significantly impact your project's performance and longevity." This statement highlights the importance of careful consideration in your choice.

When looking for a geomembrane welding machine, there are several factors to ponder. The machine's capabilities must match your project's specific requirements. Pay attention to the welding techniques, as not all machines offer the same options. For instance, some machines are better suited for thicker materials, while others excel with thinner geomembranes. Not considering these details can lead to poor performance and higher costs in the long run.

Compatibility is another critical aspect. Ensure that the welding machine you select works well with the types of geomembranes you will use. It's wise to review past projects and perhaps speak with other professionals in the industry. Remember, investing time in research can prevent potential mishaps, saving you time and money.

Understanding Geomembranes and Their Applications

Geomembranes are essential components in various industries. They provide a barrier for containment and protection against contaminants. Common applications include landfills, mining, and water reservoirs. According to industry reports, the geomembrane market is expected to reach $3.2 billion by 2025, reflecting a growing demand for effective containment solutions.

In landfills, geomembranes prevent leachate from contaminating groundwater. This is critical for environmental protection. A report by the Geosynthetic Institute indicates that improper installation can lead to serious issues. The longevity and performance of geomembranes depend on proper welding techniques. Inadequate welding may create weak points that compromise the entire system.

Mining operations also rely on geomembranes for tailings management. These liners help in stabilizing tailings and reducing the risk of spills. Nonetheless, the choice of welding machine can greatly affect the project’s success. A mismatch in technology can lead to increased costs and project delays. Continuous training is necessary. Understanding the properties of geomembranes is essential when selecting welding equipment.

Key Factors to Consider When Selecting a Welding Machine

When choosing a geomembrane welding machine, consider the material compatibility. Different geomembranes require specific welding techniques. Not every machine can handle all types. Ensure the machine you pick is suited for the thickness and type of geomembrane you will be working with. This can significantly impact the quality of the weld.

Another critical factor is the machine's ease of use. Some machines come with complex controls. User-friendly interfaces can save time and reduce errors. Look for features like adjustable temperature and speed settings, making it easier to adapt to different projects. This flexibility can be crucial in tight deadlines.

Also, consider the machine’s power source. Electric models are common, but gas-powered options exist. Each has pros and cons, depending on your work environment. Think about where you will be using the machine. Will you have access to a power source? Reflecting on these details will help you make a more informed decision.

Types of Geomembrane Welding Machines Available

When selecting a geomembrane welding machine, understanding the types available is crucial. Commonly, there are three main types: hot air welders, wedge welders, and extrusion welders. Each serves a unique purpose and caters to different project requirements. Hot air welders are favored for thin geomembranes due to their speed and ease of use. In contrast, wedge welders provide robust seams in thicker materials and are ideal for landfill applications. Extrusion welders, on the other hand, are great for filling gaps and reinforcing seams, particularly in large-scale projects.

According to a recent industry report, nearly 45% of geomembrane installations rely on wedge welding technology. This statistic highlights the importance of choosing the right machine for specific tasks. Despite these advancements, challenges persist. Operators often struggle with maintaining consistent temperature control, which can lead to weak seams. Training and experience play a significant role in addressing this issue. Many professionals are still unaware of the proper settings for different materials, potentially compromising project integrity.

Understanding these machine types and their applications can significantly enhance project outcomes. However, the risk of improper use remains. As more companies adopt advanced welding techniques, the need for proper training becomes even more critical. Continuous learning in this field is essential to avoid common pitfalls and ensure high-quality installations.

Essential Features for Efficient Geomembrane Welding

Choosing the right geomembrane welding machine relies heavily on essential features. One key factor is the heating mechanism. Efficient machines utilize advanced heating elements. These can evenly distribute heat across the welding area, helping to achieve strong and durable seams. A consistent temperature is crucial for preventing failures.

Another important feature is the speed control. Machines with adjustable speed allow users to adapt to various materials. This flexibility is vital for different project demands. Often, users overlook the importance of pressure settings. Proper pressure ensures that the seams do not weaken over time, and pressure should be easily adjustable for optimal performance.

User-friendliness is also worth considering. A clear interface simplifies operation, especially for less experienced workers. However, some machines can have overly complicated settings, which may lead to mistakes during welding. It’s helpful to have a machine that balances simplicity and functionality. Ultimately, understanding these features helps in making a wise choice.

Maintenance Tips for Prolonging Welding Machine Lifespan

Maintaining a geomembrane welding machine is essential for its longevity. Regular cleaning is necessary to remove debris and residue. A clean machine performs better and reduces wear on components. After each use, check the welding surfaces. Small imperfections can lead to larger issues down the line. A quick inspection can save time and cost later.

Routine lubrication of moving parts is crucial. It prevents wear and ensures smooth operation. Using the right lubricant makes a difference. Ensure you don't overdo it; excess lubricant may attract dirt. Also, regularly inspect electrical components. Loose connections can lead to malfunctions. It’s easy to overlook, but it’s vital for optimal performance.

Training operators on proper use is beneficial too. They should understand machine functions and limits. Misuse can lead to breakdowns, costing time and resources. Keeping a maintenance log can provide insights into patterns or recurring issues. These details can inform future maintenance strategies, fostering a proactive approach. Tools and parts should be organized but can often get messy. Staying organized is a constant challenge, but worthwhile for efficiency.